42mm Double Bender

Dual-head servo-driven bending system for rebar up to Ø42mm (#14), optimized for high-throughput rebar and precast fabrication with reduced labor needs and faster cycle times.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

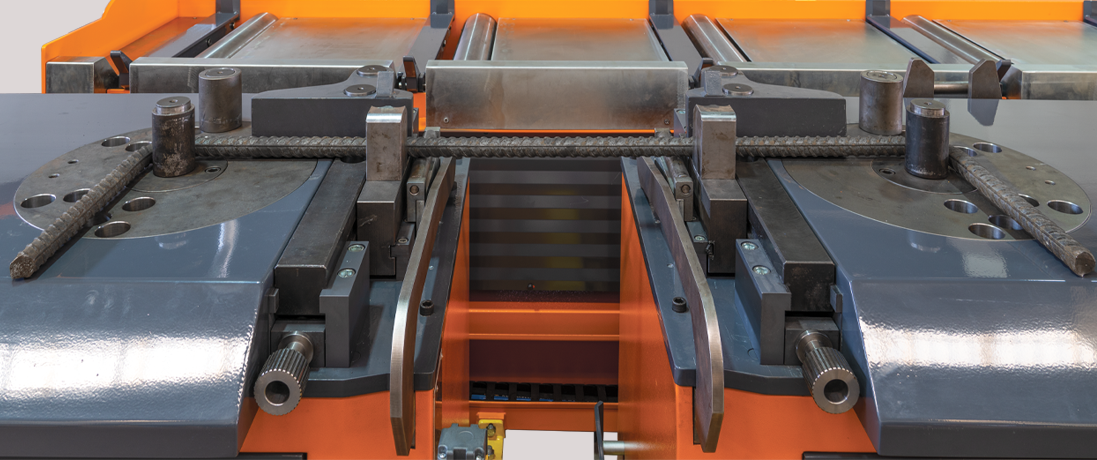

The Synclone 45S Double Bender by FMS is a high-performance rebar bending solution designed for industrial applications that demand precision, speed, and labor efficiency. Built for Ø42mm (#14) capacity, it features two independently controlled bending heads—one stationary and one mobile—powered by high-torque servo motors.

This system enables simultaneous or independent bending operations, helping factories achieve higher throughput while minimizing manual labor. The user-friendly digital interface allows for fast programming of complex bending sequences, with saved presets and optional barcode scanning for automation and traceability. Integrated pneumatic systems handle auto kick-off and part removal, while feeding is manually managed for precision loading.

Ideal for solar pile, rebar fabrication, and precast production facilities, the Synclone 45S empowers operators to manage a broad range of bending requirements with minimal training and reduced error rates.

Key Features:

- Double bender setup with servo-controlled movement

- Handles rebar up to Ø42mm (#14)

- One stationary and one mobile bending arm

- Automatic pneumatic part removal system

- Manual feeding with adjustable roller speed

- User-friendly 10.1″ digital control panel

- Bending presets and shape memory for fast recall

- Optional barcode scanning integration

- Compact design with only 1-meter spacing between benders

- Includes full mandrel set: Ø70, Ø80, Ø100, Ø110, Ø125, Ø145, Ø160, Ø180, Ø215

System Components:

Feeding Conveyor:

- Length: 14 meters (45 ft)

- Manual rebar feeding with adjustable-speed rollers

- Supports large-diameter rebar transport

Bending Units:

- Dual-bender configuration: 1 stationary, 1 movable

- Switch between full-automatic and manual operation

- Mandrel-assisted bending with tight radius capability

- Bending distance between arms: minimum 1 meter

Digital Control Panel:

- 10.1” touchscreen interface

- Fast input and recall of bending presets

- Barcode system optional

- Servo-based positioning for accuracy and speed

Part Handling & Collection:

- Pneumatic kick-off system

- 3-bin collection unit included

- Optional automatic discharging available

- Remote connection enabled for support and diagnostics

Technical Specifications:

- Bending Capacity: Ø20–Ø42 mm (#6–#14)

- Bending Sensitivity: ±5 mm

- Hydraulic System Pressure: 180 BAR / 2610 PSI

- Air Pressure Requirement: 8–10 BAR / 116–145 PSI

- Total Power: 25.2 kW / 33.8 HP

- Energy Consumption: 17.3 kWh

- Weight: 7,000 kg / 15,432 lbs

Motors:

- Stationary Bender: 7.5 kW Servo

- Moving Bender: 7.5 kW Servo

- Bender Movement Motor: 2.2 kW Servo

- Hydraulic Motor: 4 kW AC

- Roller Motor: 3 kW AC

Bending Capacities by Steel Strength & Diameter:

At 45 kg/mm²:

- Ø42 / #14: 1 piece

- Ø36 / #11: 1 piece

- Ø30 / #10: 2 pieces

- Ø24 / #8: 3 pieces

- Ø20 / #6: 4 pieces

At 65 kg/mm²:

- Ø36 / #11: 1 piece

- Ø30 / #10: 2 pieces

- Ø24 / #8: 3 pieces

- Ø20 / #6: 4 pieces

At 85 kg/mm²:

- Ø36 / #11: 1 piece

- Ø30 / #10: 1 piece

- Ø24 / #8: 2 pieces

- Ø20 / #6: 4 pieces

Reviews

There are no reviews yet.