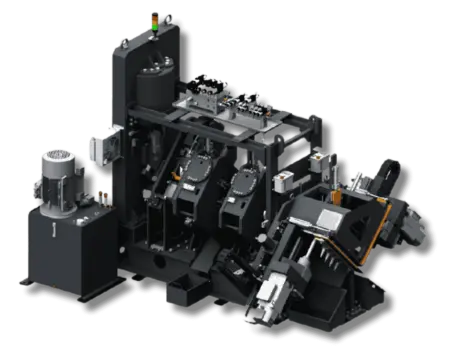

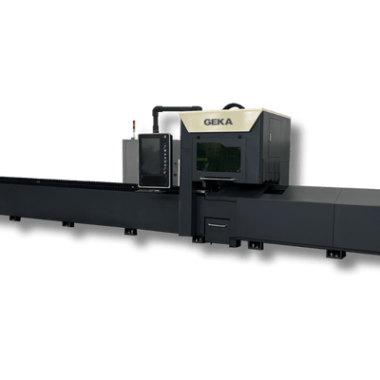

Angle and Flat Bar Processing Line

FMS Angle and Flat Bar Processing Line for Solar Structures

Designed for high-efficiency solar pile fabrication, the FMS Angle and Flat Bar Processing Line delivers automatic punching and shearing of W6 and W8 beam flanges. With CNC control, powerful tooling, and full profile automation, it’s the ideal solution for structural steel processing in solar applications.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

The FMS Angle and Flat Bar Processing Line is a high-performance CNC solution for automated punching, shearing, drilling, and marking of angle and flat bar profiles used in solar tracker systems and structural applications. With rack-and-pinion precision feeding, powerful tooling, and zero-waste optimization, this line delivers consistent, high-throughput results across a range of materials and sizes.

Key Features:

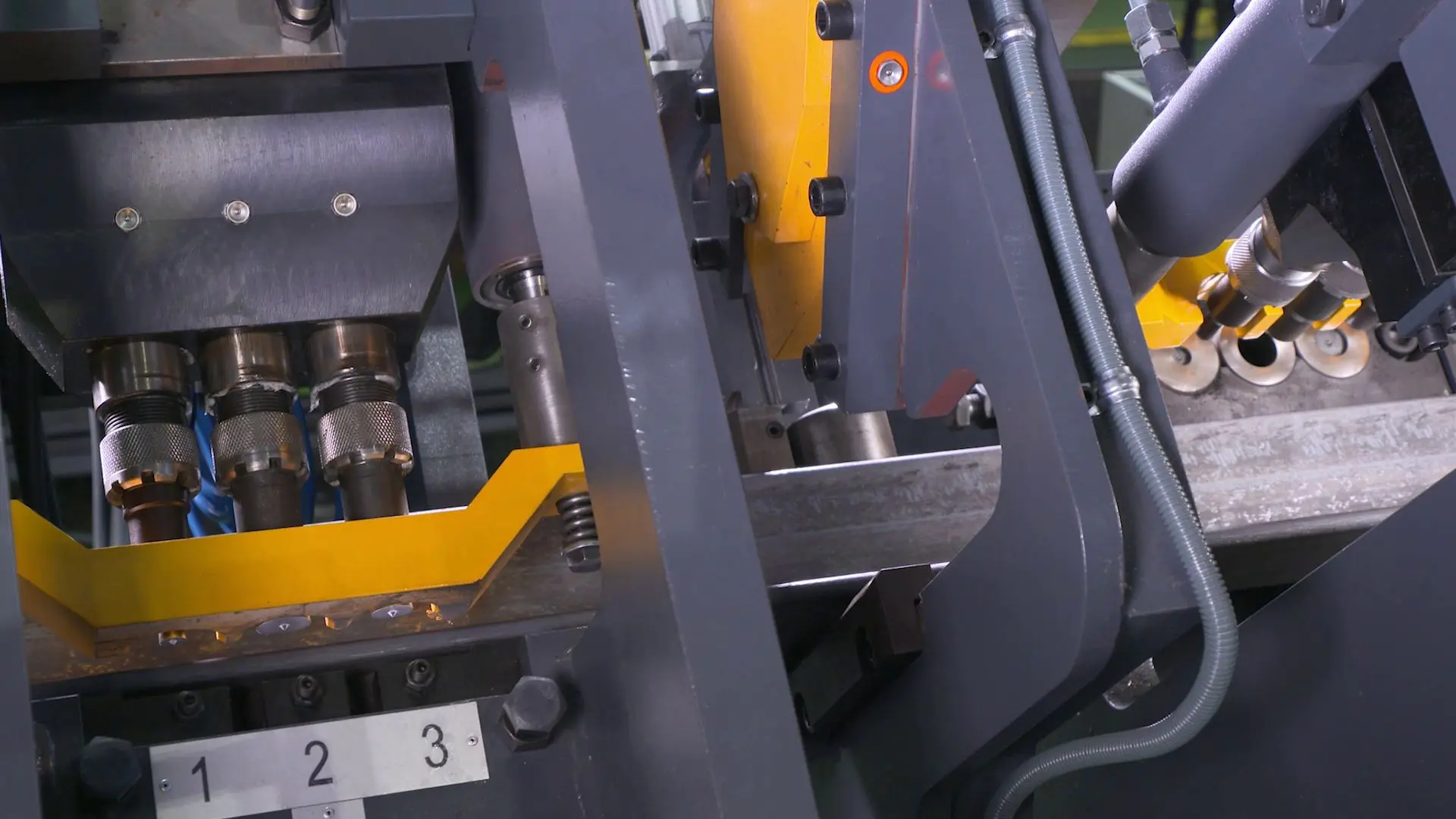

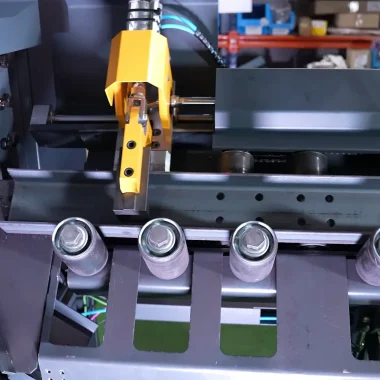

Punching Unit

- Up to three punches per leg for complex patterns

- CNC-controlled positioning and backmarking

- Quick-change punch and die system for reduced downtime

- Supports Ø31 mm punching in material up to 15 mm thick

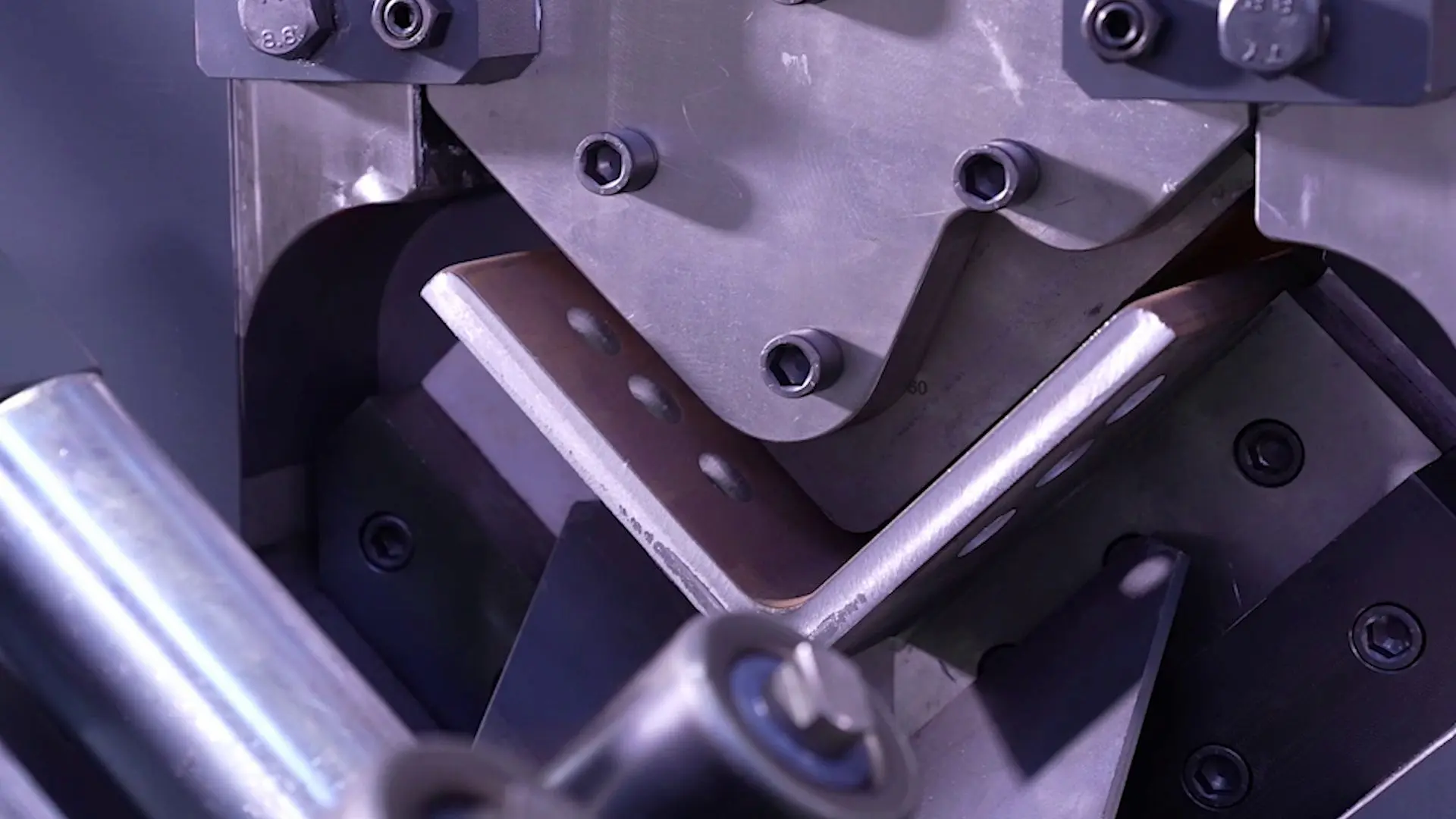

Shearing Unit

- No-waste shear station with up to 560 tons of capacity

- Quick-change blades and CNC-adjustable stroke

- Optional integrated disc-sawing station for larger profiles

Drilling Unit

- Dual 9 kW drilling heads, one per flange

- Ø40 mm capacity with ISO 40 tool holders

- 5-position automatic tool changer with internal lubrication

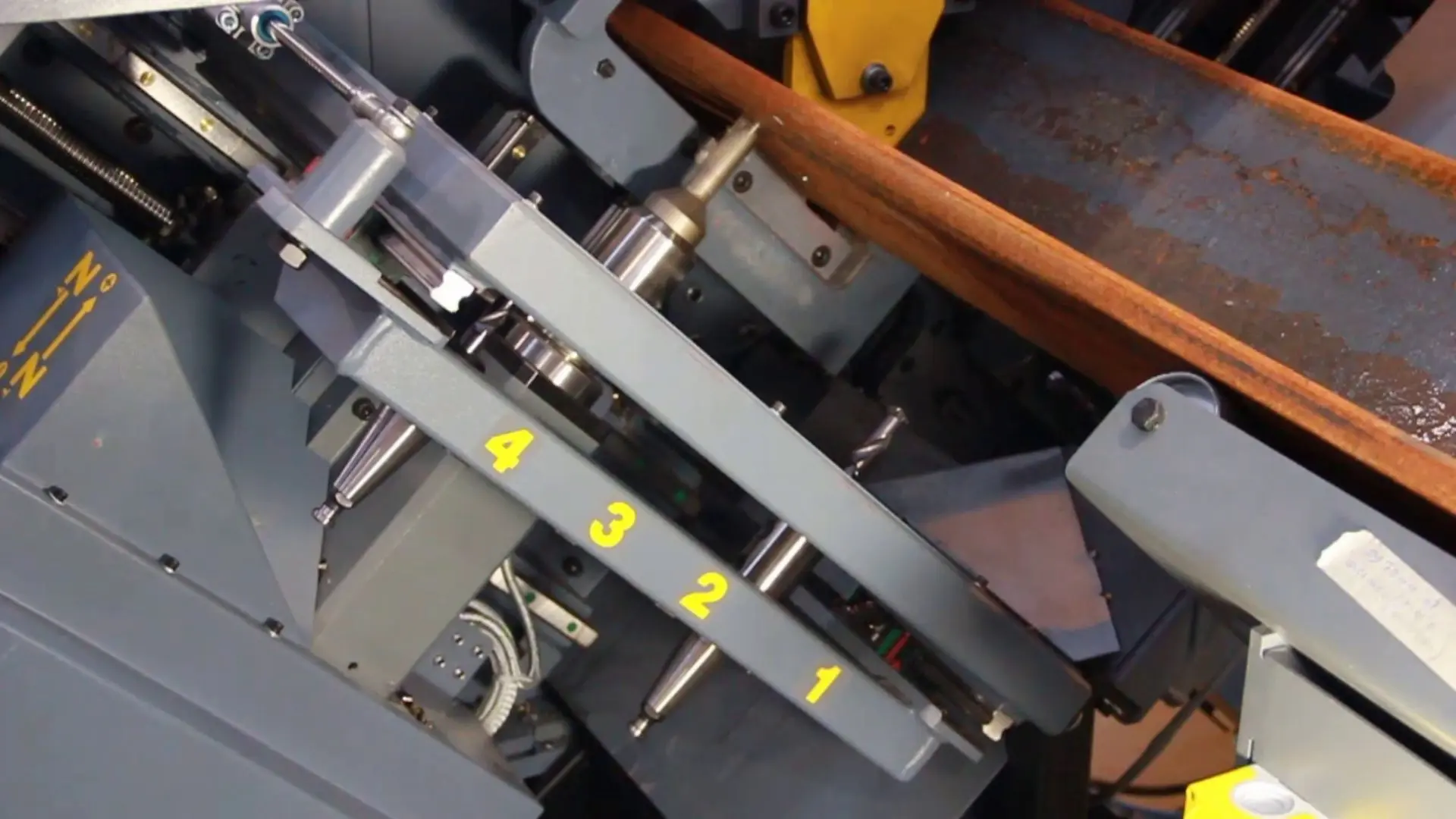

Feeding & Handling

- Rack-and-pinion infeed with rotary encoder for ±0.15 mm/m accuracy

- Processing speeds up to 60 m/min

- Automatic loading via chain conveyors

- Motorized tilt-table outfeed for continuous production

Marking Unit

- Hydraulic cassette or wheel marking for alphanumeric codes

- Up to 20 characters per stroke, CNC-controlled positioning

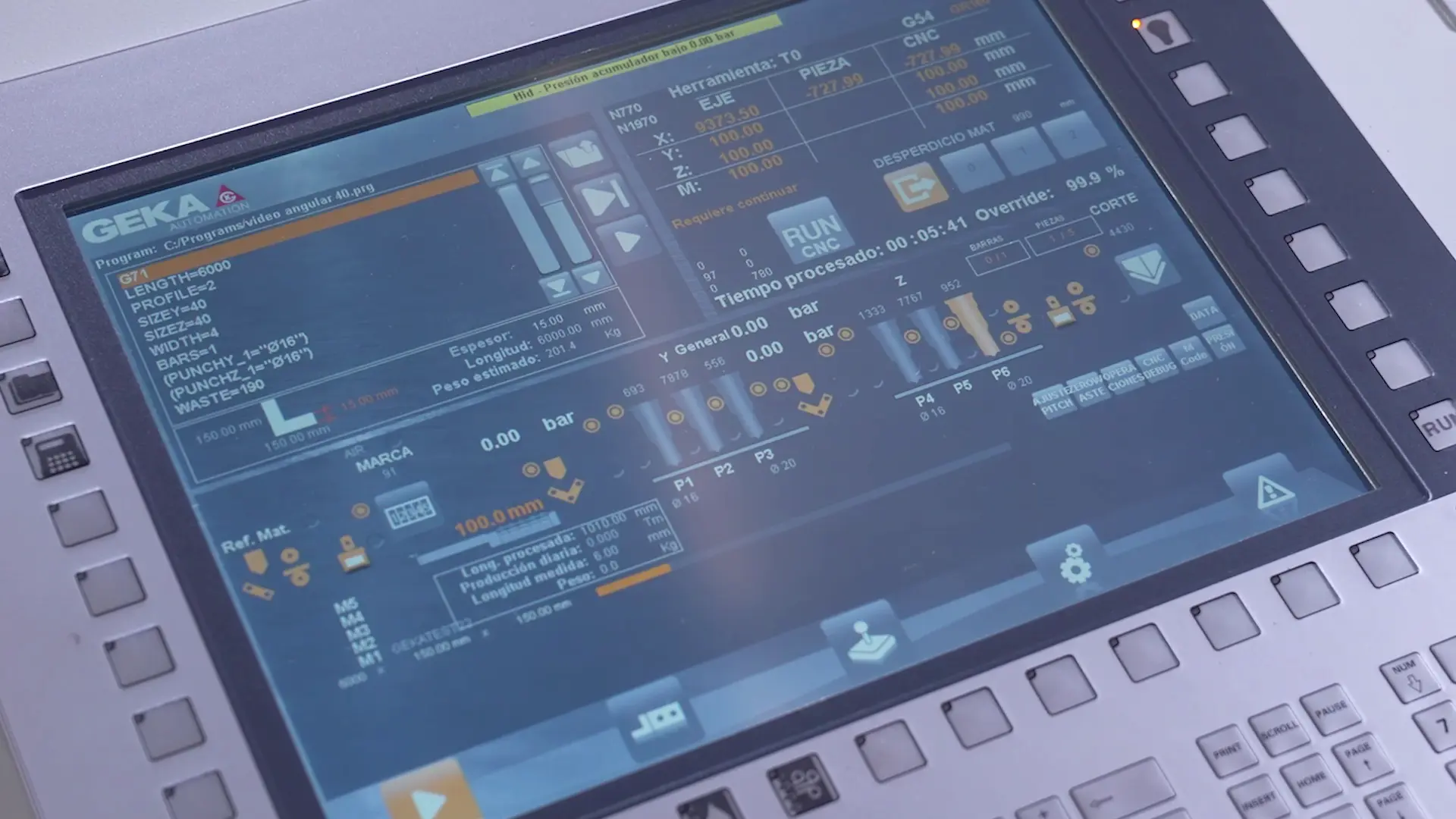

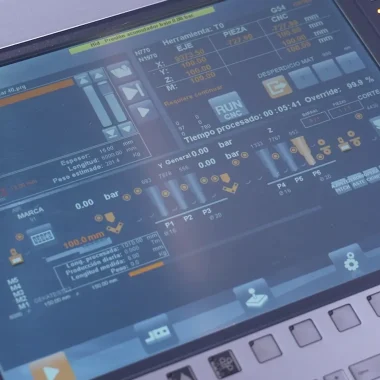

Control & Software

- Windows 10 PC with 15″ touchscreen interface

- Integrated USB and RJ45 network connectivity

- Lantek Flex3D Steelwork for simulation, collision detection, and material optimization

Available in multiple models ranging from compact units for profiles as small as 1.5″ x 1.5″ x 1/8″, to heavy-duty systems capable of processing angle up to 10″ x 10″ x 1″ and flat bar up to 12″ wide. Optional C-channel processing is available in select models.

This system is ideal for solar manufacturers and steel fabricators seeking maximum flexibility, zero scrap, and high-speed output in a single, modular line.

Reviews

There are no reviews yet.