FMS provides scalable solutions for structural fabricators—whether you’re processing hundreds or thousands of tons per month. Our beam processing equipment is built for heavy-duty performance and features world-class components from Siemens and Mitsubishi. We offer turnkey systems and layout planning tailored to your shop’s workflow and budget.

-

The A3DAM 1200 is a 10-axis robotic solution built for advanced beam processing applications. Designed to handle complex cutting, beveling, or welding tasks on structural steel, this system offers full multi-directional motion and precision automation—ideal for fabricators who need high efficiency and unmatched accuracy on large-scale projects.

-

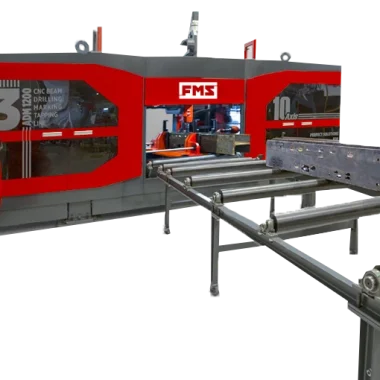

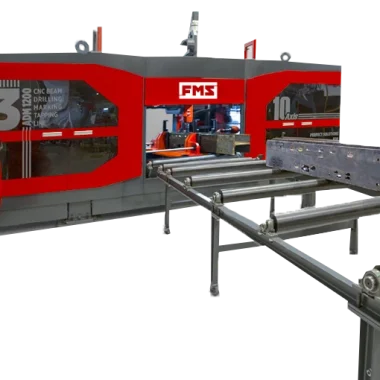

This advanced 3-spindle beam line features automatic tool changing for increased efficiency and precision. Available with optional loading and unloading arms, the system supports tandem or split layouts to fit your shop’s needs. It includes a dual-column miter saw with full-length automated measuring, part marking, and DSTV file import compatibility from TEKLA or SDS/2.

-

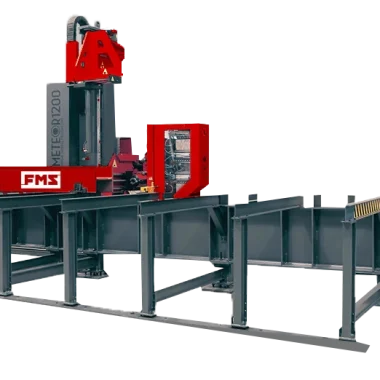

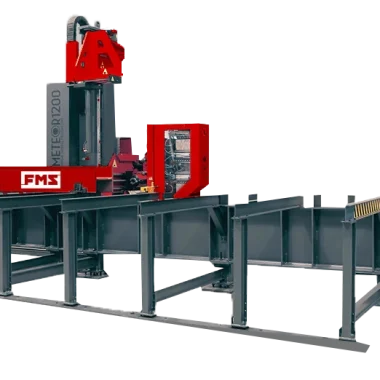

The Meteor 1200 is a high-speed, single-spindle drilling system featuring an automatic tool changer and a 20-foot table. Designed to boost productivity, this compact beam line replaces manual mag-base drilling with a precision measuring system and rapid 3-second hole cycles—ideal for shops ready to upgrade their throughput and accuracy.