-

-

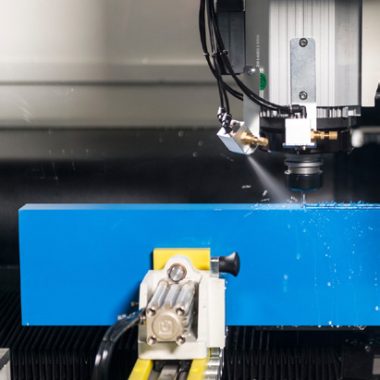

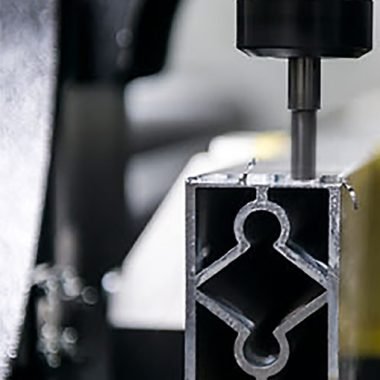

5-axis CNC machining for aluminum profile fabrication

-

Axis B: 360° rotation | Axis A: 180° swing for full-angle flexibility

-

Performs cutting, drilling, notching, marking, and drainage channel creation

-

Supports complex and non-standard profile operations

-

High processing capacity: 580 mm x 340 mm

-

Designed for high precision and efficiency in demanding environments

-

-

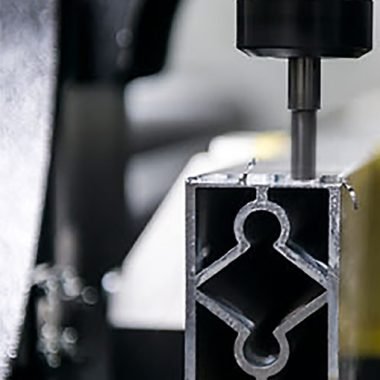

3+1 axis CNC machining for aluminum and PVC profiles

-

Spindle operates at fixed angles: -90°, 0°, +90°

-

Performs milling, drilling, drain channel cutting, punching, and marking

-

Suitable for both standard and complex profile operations

-

Processing capacity: 340 mm x 255 mm

-

Compact design with high performance and flexibility

-

-

4-axis CNC machining center for aluminum and PVC profiles

-

Fixed-angle spindle movement from -90° to +90°

-

Performs milling, drilling, punching, marking, and end milling

-

Handles profile sizes up to 340 mm x 255 mm

-

Ideal for both standard and custom fabrication tasks

-

Compact design with high productivity and precision

-

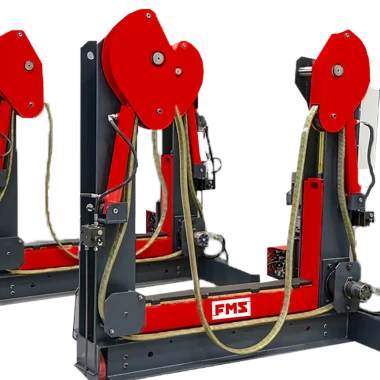

High Tech Band Saws: Precision and Performance for Every Application

FMS offers an advanced range of High Tech Band Saws, designed to meet the demands of various cutting applications with ease and precision. These machines are engineered with cutting-edge technology, including intelligent sawing systems, high torque motors, and ergonomic designs, ensuring optimal performance across industries. With automatic load/unload solutions, customizable material handling, and a variety of smart operation modes, FMS band saws are built for efficiency and accuracy.

Whether you’re processing solid materials or complex cuts, these band saws can adjust to meet your specific needs, delivering reliable, high-quality results.

-

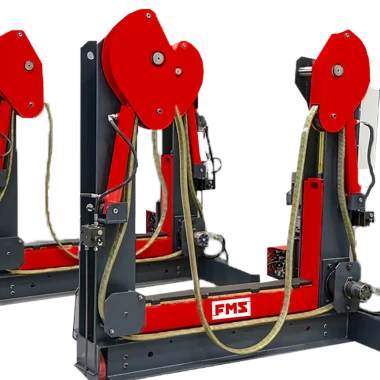

The HR Rope Rotator uses high-capacity stranded steel cables with an industrial protective coating to safely rotate heavy components. Designed to handle virtually any shape that fits within its frame, this system has transformed material handling workflows in structural steel, job shops, and beyond—boosting safety and efficiency on the floor.

-

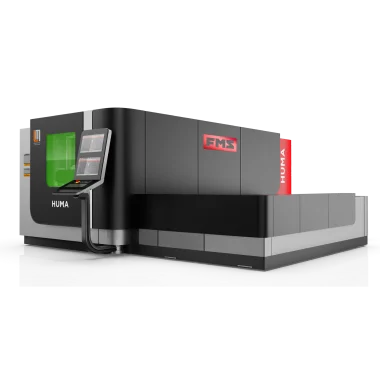

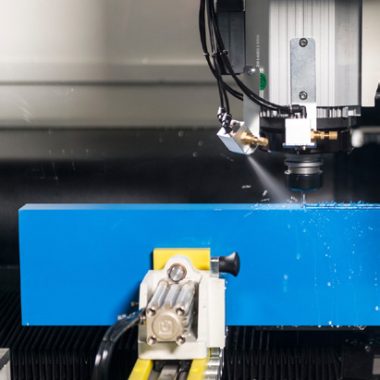

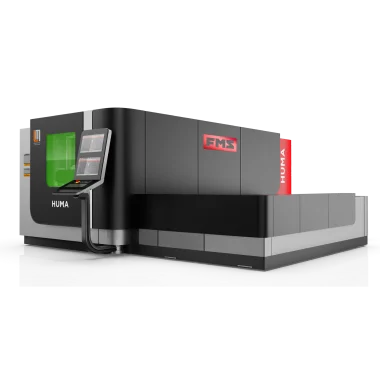

Smart. Efficient. Space-saving. The Huma fiber laser delivers precision cutting in a compact footprint—ideal for modern workshops. Engineered for speed and optimized for non-ferrous metals, Huma is the perfect blend of performance and practicality in fiber laser technology.

-

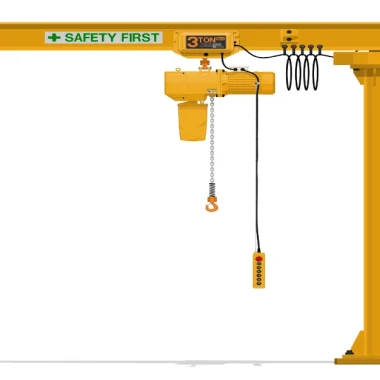

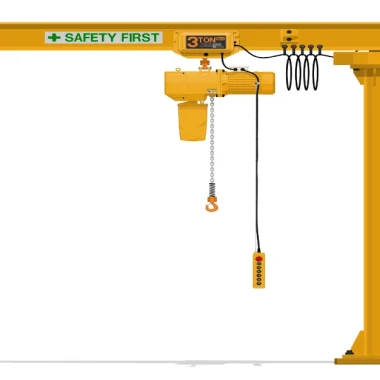

FMS’s I-Beam Jib Cranes offer simple, versatile lifting solutions for localized material handling needs. These cranes are ideal for workstations, loading docks, and production areas where repetitive lifting and precision placement are essential.

Constructed with rugged steel I-beams, they provide strong load support and smooth 180° to 360° rotation, depending on mounting style. Available in wall-mounted or floor-mounted configurations, I-Beam Jib Cranes can be tailored to fit your space and workflow.

With quick installation and low maintenance, these cranes are a practical and efficient addition to any facility where safety, control, and productivity are key.

-

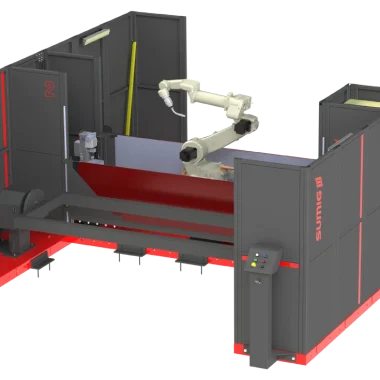

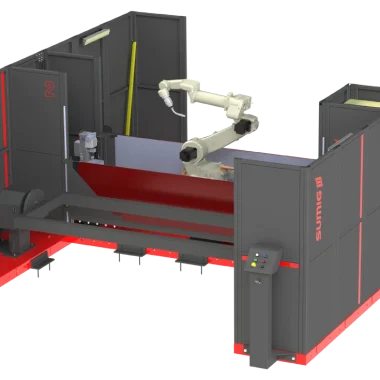

A high-performance dual-station robotic weld cell designed for medium to large parts, offering flexible configuration, safety features, and future scalability.

-

A compact, pedestal-mounted cold saw designed for precision mitre cuts in metal workshops and toolrooms. Ideal for small batch jobs and general-purpose cutting, with manual operation and a rugged build.

-

Manual Miter Cutting Band Saws

The KMT CRAFT series of manual band saws offers an affordable and efficient solution for users who need simple and reliable miter cutting capabilities. Built with a pivot-type body design, these machines allow for flexible miter cutting, with some models offering dual-directional angle adjustment. All models in this category feature fully manual operation, including vise clamping, material feeding, angle adjustment, and body movement. These machines are a great fit for light to medium-duty workshops that value versatility and hands-on control.

-

1 Axis, 3 Axis or more

Mandrel

1in. up to 12in.

-

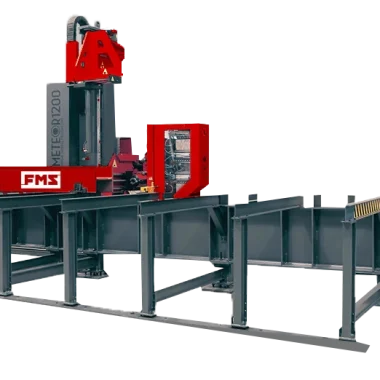

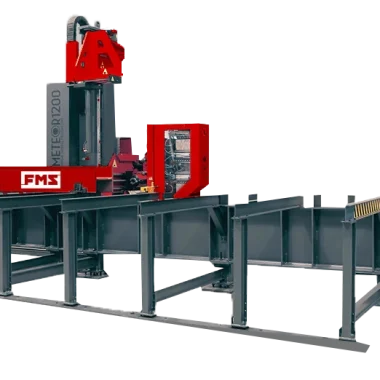

The Meteor 1200 is a high-speed, single-spindle drilling system featuring an automatic tool changer and a 20-foot table. Designed to boost productivity, this compact beam line replaces manual mag-base drilling with a precision measuring system and rapid 3-second hole cycles—ideal for shops ready to upgrade their throughput and accuracy.