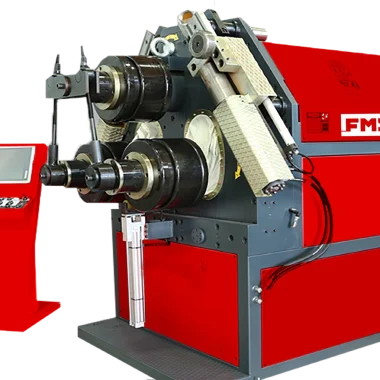

Non-Mandrel Rotary Draw Bender

Available from 1 in. up to 6 in. pipe and tube.

The FMS Prodcut is designed as a heavy duty precision platform to meet the long term production demands of the most demanding applications. Pick your width and length from our standard offerings or design a custom size to fit your unique situation. Every ProCut is supplied with the industry standard HyperTherm Plasma. FMS can assist in your buying process by providing cut samples, speeds of cut, quality and accuracy specs to meet your specific needs.

Select your table size and plasma power size and add any of our productivity options to enhance your capabilities even further:

Available Options

Tube Cutting

Bevel Cutting

Oxy-Fuel Cutting

HyperTherm Software Nesting & Cutting Solutions

Pipe

Tube- round, square, and rectangle

Angle Iron

Channel

Flat Bar

Tee’s

Structural Shapes

For heavy-duty operations requiring greater stability and cutting precision, the Double Column Semi-Auto Miter Band Saws deliver. Built with a rugged twin-post structure, these machines minimize vibration and ensure smooth motion—especially when cutting large or dense materials. All models feature dual-direction miter cutting (-45° to 60°) and are equipped with linear guides, hydraulic vises, and digital control panels.

These machines are best suited for shops or operations dealing with oversized or high-volume workpieces and where precision is non-negotiable.

Model Highlights:

KDG 700×1250 DM / 560×1050 DM: Designed for maximum capacity and stability, featuring the full range of dual-angle cuts and advanced motion control.

KDG 460×800 DM: Slightly more compact but with all the professional-grade features of the larger models, ideal for mid-size operations with high standards.

The double column models prioritize accuracy, consistency, and reduced operator fatigue, making them a perfect choice for users working in industrial or production-level environments.

The Pivot-Type Semi-Auto Miter Band Saws are engineered for reliability, flexibility, and simplicity in miter cutting. Designed with a pivoting saw arm, these models are capable of cutting angles from 0° to 60°, with some models extending the range to -45° for dual-direction cuts. All machines in this series use manual material feed, while the hydraulic vise and lift system simplify operation and improve efficiency.

These models are ideal for workshops that handle a range of profiles and materials, offering dependable performance for small to mid-sized cutting tasks.

Model Highlights:

KDG 400×580 / 350×570 / 300×500: Standard pivot models with 0°–60° cutting range and hydraulic lift after cut.

KDG 220×310 DM: Includes dual-direction mitering (-45° to 60°) and a pneumatic vise for quick clamping (hydraulic optional).

KDG 400×610 DM: Combines pivot design with dual-direction cutting, perfect for added flexibility without jumping to a double-column system.

Each of these models offers essential features for clean, efficient miter cuts—making them an excellent fit for users who need semi-automation without the footprint or price tag of a full industrial setup.

These semi-automatic band saws feature a double column body design, ideal for cutting large or dense materials where stability and precision matter most. With linear guide systems and hydraulic-powered movements, they deliver vibration-free, accurate cuts every time. Operators can control the process easily via a digital control panel, while manual material feeding gives flexibility for custom cuts.

These semi-automatic band saws with pivot-type bodies are ideal for shops that value space efficiency and easy operation. They’re equipped with hydraulic vises for secure clamping and automatic return after cuts. Manual feeding and simple controls make them a solid choice for routine, straight-cutting jobs in smaller work environments.

The V 315HX is a semi-automatic circular cold saw designed for fast, precise cutting of various metal pipe and profile sizes. Ideal for short production runs and heavy-duty applications, it features foot-pedal control, smooth hydro-pneumatic saw head descent, and a wide cutting angle range from 45° left to 45° right.

Built for versatility and precision, the FMS 66 S delivers dependable performance across five integrated workstations. With a rugged single-cylinder design, this ironworker handles flat bar, angle, round bar, punching, and notching with ease. Ideal for shops needing compact power and efficiency without sacrificing capability.

Standard capacity includes 12″ x 9/16″ flat bar, 4″ x 4″ x 7/16″ angle, and up to 1-1/2″ round bar. The punch station handles 1-1/4″ x 5/8″, and the notcher delivers clean cuts at 1-5/8″ x 3-15/16″ x 3/8″. Each machine comes equipped with an electric backstop, built-in work light, and a complete tooling package.

Optional attachments include a press brake, channel blades, and custom shapes to suit your unique shop needs.

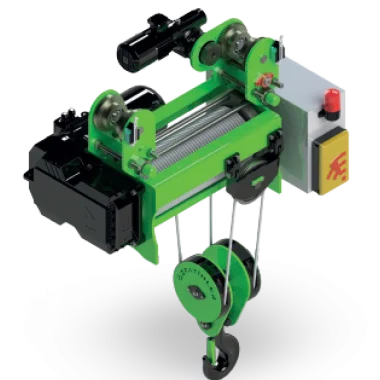

FMS’s Single Girder Electric Overhead Traveling (EOT) Cranes offer a reliable and cost-effective solution for light to medium-duty material handling. Designed for efficiency and ease of installation, these cranes are ideal for applications requiring lower load capacities and faster operation within limited headroom environments.

Built with a compact structure and reduced dead weight, Single Girder EOT Cranes are well-suited for workshops, warehouses, fabrication shops, and production lines. Despite their lighter build, they maintain strong load control and meet relevant industry safety standards.

Whether you’re moving equipment, parts, or assemblies, FMS’s single girder solutions are engineered to maximize floor space and lifting height while keeping operational costs low.

The LEO R is an automatic front blade saw designed with 2-axis servo control, ideal for cutting aluminum and PVC profiles. Offering precise cutting with angles between -22.5° and 45°, it is built for high-efficiency, especially for cutting wider profiles.

Compact, efficient, and made for precision. The Tulpar fiber laser is perfect for shops that need high-quality cuts in thin to medium sheet metal without sacrificing floor space. With low power consumption and smart automation, Tulpar delivers professional-grade performance at an approachable scale.

No products in the cart.