Matrix 55

Heavy-duty hydraulic shearline built for high-volume rebar cutting up to 55mm (#14), with automated conveyors, precision digital controls, and efficient material handling.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

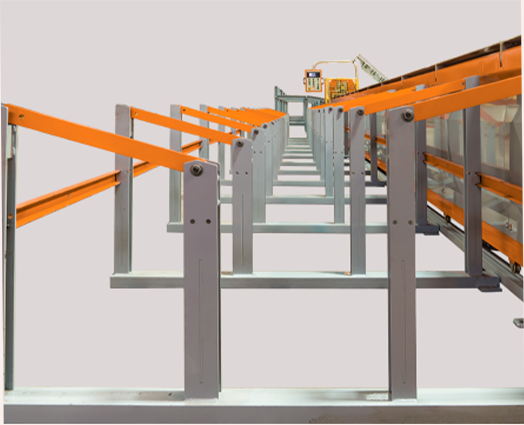

The Matrix 55 Hydraulic Shearline from FMS is a complete industrial solution for processing large volumes of rebar with speed and precision. Designed for rebar up to 55mm (#14), this system features a digital control panel with 360° rebar positioning, adjustable cut lengths, and servo-controlled movement for reliable cutting accuracy.

Its robust build includes galvanized steel infeed and outfeed conveyors with automatic sliding rollers, along with modular collecting bins for easy sorting. The heat-treated hydraulic cutting unit is built for long-lasting durability under continuous use, and its sensitive measuring system ensures ±3 mm cutting precision across a wide range of bar sizes and strengths.

Key Features:

- Cuts rebar up to Ø55mm (#14)

- Digital control panel with 10.1” touchscreen

- 360° material positioning with automated rollers

- Servo-controlled stopper for accurate cutting

- ±3 mm cutting tolerance

- Manual or automatic bin unloading

- Modular bin design for customizable sorting

- Remote connection/control capability

- Galvanized steel conveyor system for durability

System Components:

Infeed Conveyor & Loading Platform:

- 12 meters (40 ft) long

- Automatic sliding rollers

- Galvanized steel construction

Hydraulic Cutting Unit:

- Heat-treated steel body

- Built for high-force, high-precision cuts

- Stationary for stability and accuracy

Outfeed Conveyor & Collecting Bins:

- 6 meters (20 ft) outfeed with automatic rollers

- 2-bin modular system with adjustable pockets

- Manual arm control, automatic unloading available

Technical Specifications:

- Cutting Sensitivity: ±3 mm

- Total Power: 15.85 kW (21.2 HP)

- Energy Consumption: 14.65 kWh

- Hydraulic System Pressure: 250 bar / 3625 PSI

- Voltage: 380V

- Hydraulic Motor: 7.5 kW (9.38 HP)

- Loading Roller Motors: 3 × 1.1 kW

- Discharge Roller Motor: 1 × 0.75 kW

- Stopper Motor: 0.75 kW (servo controlled)

- Control Panel: PLC with 10.1″ digital screen

- Weight: 5200 kg / 11,464 lbs

Cutting Capacity by Steel Strength & Diameter:

At 45 kg/mm²:

- Ø55 / #14: 1 piece

- Ø40 / #14: 5 pieces

- Ø36 / #11: 6 pieces

- Ø32 / #10: 7 pieces

- Ø28 / #9: 8 pieces

- Ø26 / #8: 11 pieces

At 65 kg/mm²:

- Ø55 / #14: 1 piece

- Ø40 / #14: 4 pieces

- Ø36 / #11: 5 pieces

At 85 kg/mm²:

- Ø55 / #14: 1 piece

- Ø40 / #14: 4 pieces

- Ø36 / #11: 5 pieces

- Ø32 / #10: 6 pieces

- Ø28 / #9: 7 pieces

- Ø26 / #8: 10 pieces

- Ø22 / #7: 13 pieces

- Ø20 / #6: 14 pieces

- Ø16 / #5: 18 pieces

- Ø12 / #4: 24 pieces

- Ø10 / #3: 30 pieces

- Ø8 / #3: 35 pieces

Reviews

There are no reviews yet.