Matrix 55S

Automated hydraulic shearline for cutting rebar up to 55mm (#14), featuring two-sided conveyors, servo-controlled measurement, and labor-saving digital programming.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

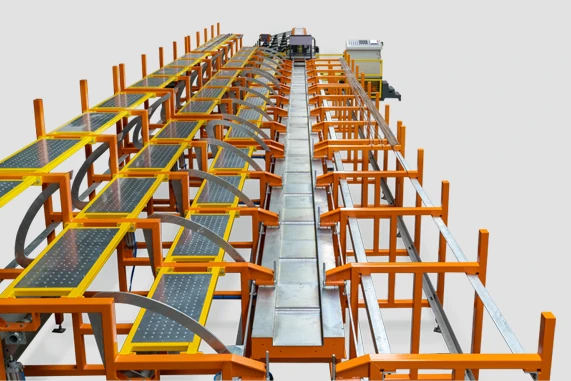

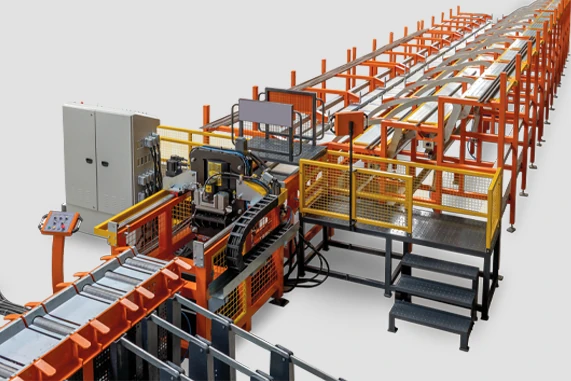

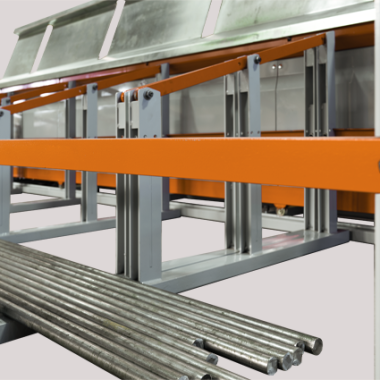

The Matrix 55S from FMS is a next-generation hydraulic rebar shearline engineered to maximize productivity and reduce labor requirements. Designed to handle heavy-duty rebar up to Ø55mm (#14), it features an expanded dual-side operator platform, three-story infeed racks, and automatic unloading bins for efficient material flow and reduced manual handling.

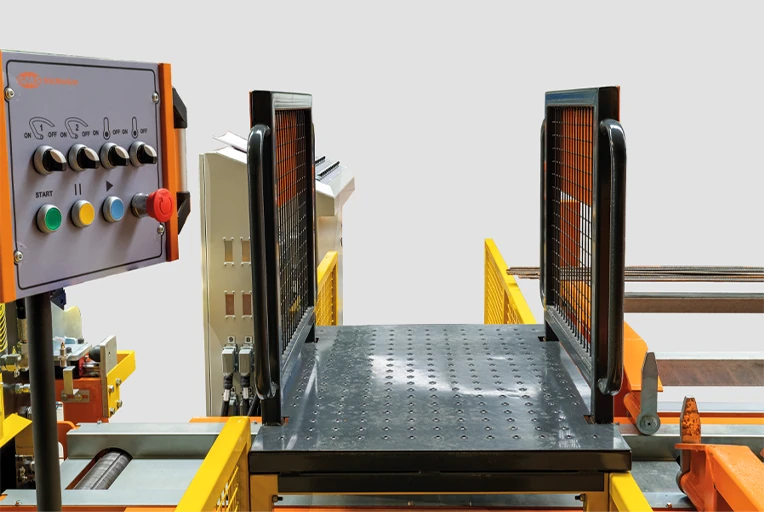

The system’s intelligent digital control panel allows one operator to manage all machine functions, including servo-controlled cut length programming, movement of the cutting head, and remote access for support. With ±3 mm cutting precision, 360° positioning, and optional barcode scanning for job automation, the Matrix 55S delivers industrial-grade performance with minimal oversight.

Its robust modular design, powered by hydraulic and pneumatic systems, is ideal for high-throughput solar pile fabrication and commercial construction operations.

Key Features:

- Cuts rebar up to Ø55mm (#14)

- Two-sided infeed loading platform with multi-level storage

- Servo-controlled cutting and measuring system

- ±3 mm cutting accuracy

- PLC touchscreen control with Windows-based interface

- Optional barcode scanning system

- Fully automated bin unloading with pneumatic arms

- Remote connection and diagnostics supported

- Heavy-duty build with hydraulic and pneumatic integration

System Components:

Infeed Conveyor & Loading Platform:

- Length: 12 or 18 meters (40–60 ft)

- 3-story loading rack on one side, 1-story on the other

- Galvanized steel construction

- Auto sliding rollers for rebar movement

Operator Platform & Control Panel:

- 10.1” touchscreen (Windows-based)

- Controls full automation or manual functions

- Barcode scanning system available

- Remote control and connectivity

Main Hydraulic Cutting Unit:

- Moveable body: slides up to 1 meter for flexible positioning

- Hydraulic and servo-assisted movement

- ±3 mm cutting sensitivity

Outfeed Conveyor & Collecting Bins:

- 6 meters (20 ft) dual-side outfeed system

- 4-bin layout per side (8 total)

- Pneumatic auto-opening arms

- Modular pocket layout adjustable in length

- Auto unloading to designated bin

Technical Specifications:

- Cutting Capacity: Ø6–Ø55 mm (#3–#14)

- Cutting Sensitivity: ±3 mm

- Total Power: 18.9 kW (25.3 HP)

- Energy Consumption: 14.65 kWh

- System Pressure (Hydraulic): 250 bar / 3625 PSI

- Air Pressure (Pneumatic): 8–10 bar / 116–145 PSI

- Weight: 17,000 kg / 37,460 lbs

- Digital Control: PLC touchscreen, remote-capable

- Barcode System: Optional

Motors:

- Hydraulic Motor: 7.5 kW (9.38 HP)

- Loading Rollers: 3 × 1.1 kW

- Discharge Rollers: 3 × 1.1 kW

- Stopper Motor (servo): 1.5 kW

Cutting Capacity by Steel Strength & Diameter:

At 45 kg/mm²:

- Ø55 / #14: 1 piece

- Ø40 / #14: 5 pieces

- Ø36 / #11: 6 pieces

- Ø32 / #10: 7 pieces

- Ø28 / #9: 8 pieces

- Ø26 / #8: 11 pieces

- Ø22 / #7: 13 pieces

- Ø20 / #6: 14 pieces

- Ø16 / #5: 18 pieces

- Ø12 / #4: 24 pieces

- Ø10 / #3: 30 pieces

- Ø8 / #3: 35 pieces

At 65 kg/mm²: Same quantities as above except Ø40 and Ø36 reduce by 1 piece each

At 85 kg/mm²: Same as 65 kg/mm²

Reviews

There are no reviews yet.