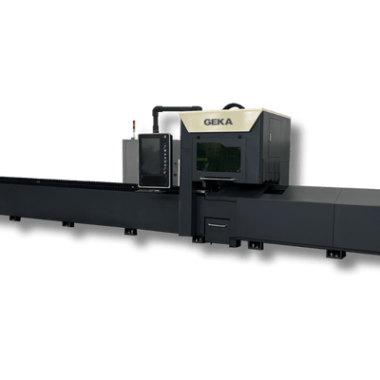

Hydraulic Punching Machine for Solar Piles

FMS Hydraulic Punching Machine for Solar Piles

Built for strength, flexibility, and high-output beam processing, the FMS Hydraulic Punching Machine delivers up to 440 tons of force and simultaneous punching on both flanges—perfect for W-beam profiles in solar tracker and pile foundations. Add the optional Shear Master module for a complete punch-and-shear line.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

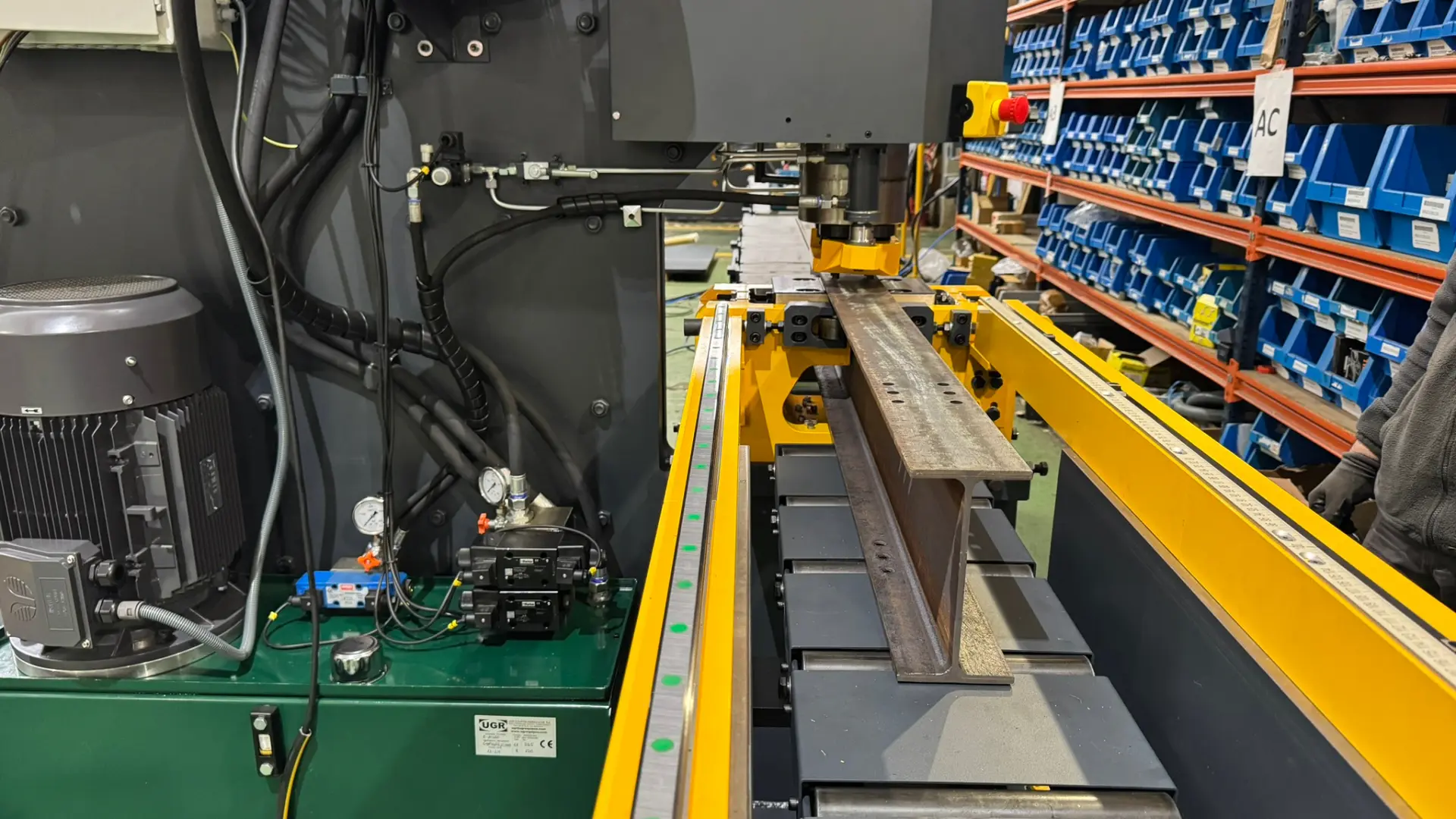

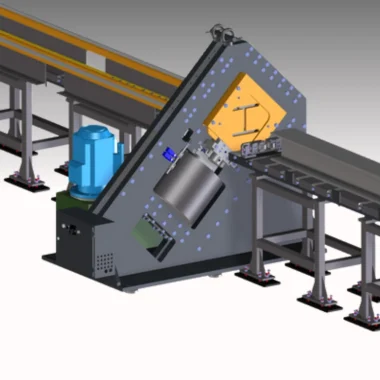

The FMS Hydraulic Punching Machine for Solar Piles (powered by the PUMA 2HI system) is a manual punching solution designed for steel beams used in solar mounting and structural steel applications. Engineered to maximize productivity and precision, this modular system handles beams up to 9 meters (approx. 30′) with flexible punching patterns, scalable force, and optional integrated shearing.

Key Features:

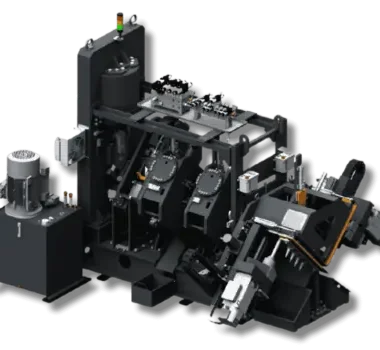

Punching Unit:

- Up to 2, 4, 6, or 8 holes in a single stroke

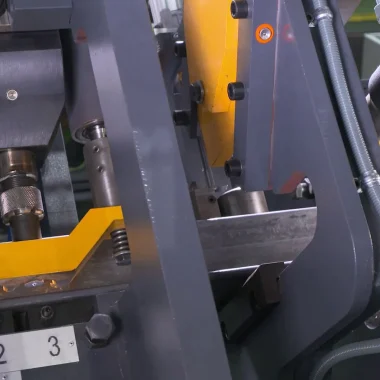

- Double-head tandem design for simultaneous flange punching—no need to rotate the beam

- Compatible with round and oblong punches

- Punching force options: 165, 220, or 440 tons (dual-head)

- Max flange thickness: ¾”

- Max punch diameter: 1.57″

Material Handling & Alignment:

- Manual feeding via idle rollers (supports beams up to 9 meters / ~30′)

- Alignment rollers with adjustable or fixed height options

- Dual roller web alignment for symmetrical hole placement

Flexibility & Scalability:

- Modular system adapts to varying hole patterns and production needs

- Optional Shear Master integration for high-powered beam shearing

- Ideal for solar pile systems, tracker structures, and general structural steel applications

Technical Range (Model Variants):

| Model | Punching Force | Max Flange Thickness | Max Punch Diameter |

|---|---|---|---|

| PUMA 2HI 165 | 181 US Tons | ¾” | 1.57″ |

| PUMA 2HI 220 | 240 US Tons | ¾” | 1.57″ |

| PUMA 2HI 440 | 480 US Tons (2×240) | ¾” | 1.57″ |

When paired with the Shear Master cutting module, the system becomes a full-service beam processing line—delivering high-throughput, low-waste manufacturing for the solar construction industry.

Reviews

There are no reviews yet.