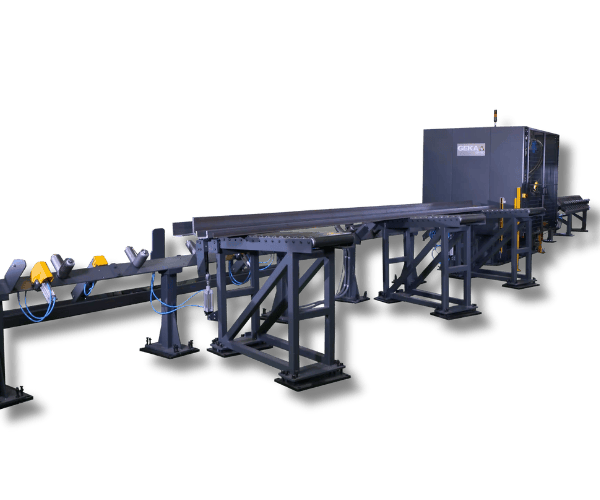

Beam Processing Line

FMS Beam Processing Line for Solar Pile Systems

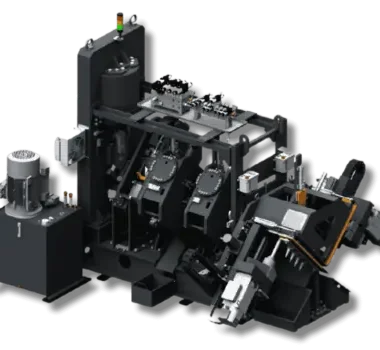

Built for speed, versatility, and zero-waste performance, the FMS Beam Processing Line automates the punching and shearing of angle and C-channel profiles used in solar pile and structural steel fabrication. CNC precision and advanced material handling make it a scalable solution for high-throughput environments.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

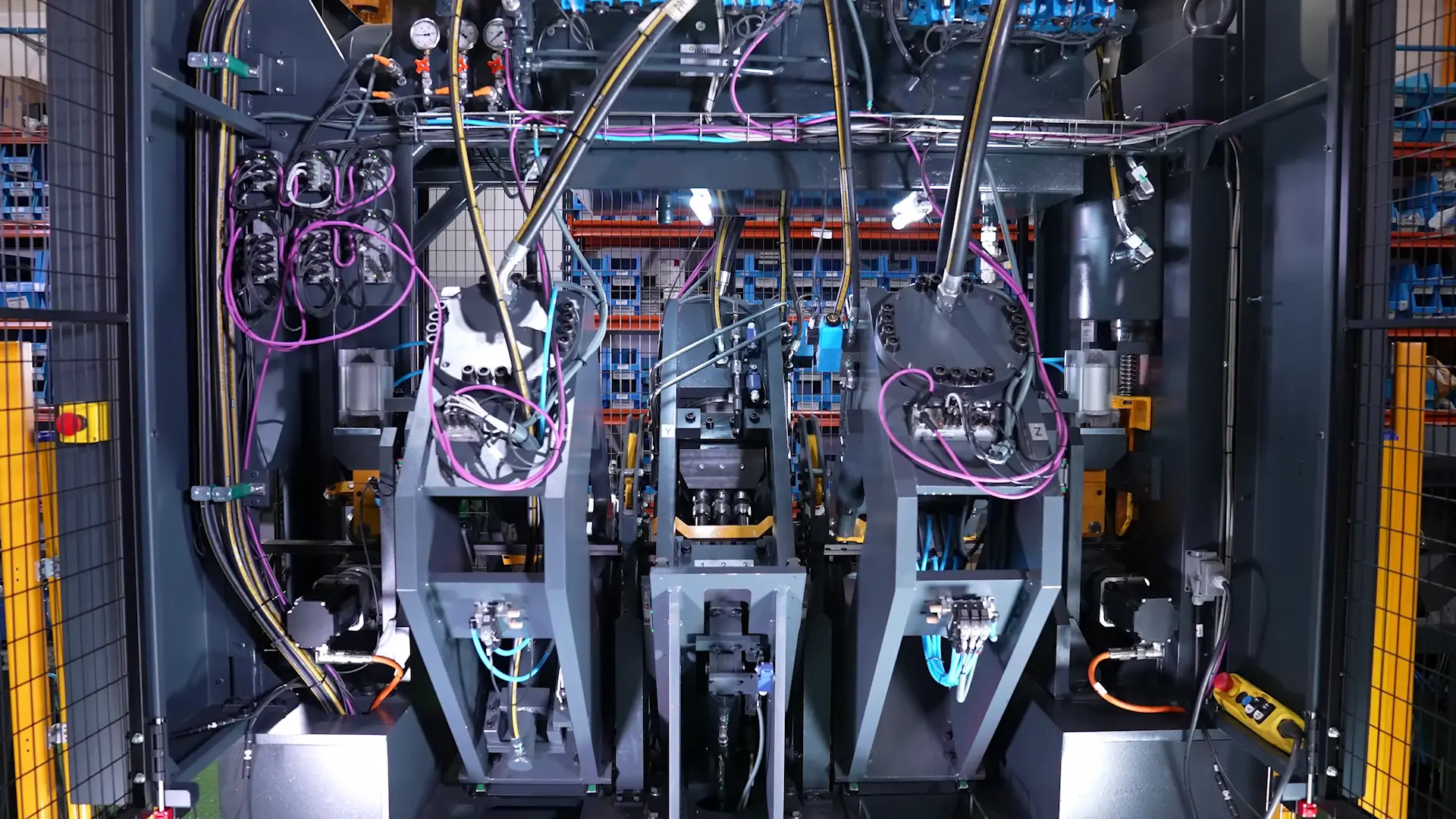

FMS Beam Processing Line for Solar Pile Systems combines CNC-driven punching, shearing, and profile handling in a robust system engineered for manufacturing solar pile components, power transmission towers, and other structural applications. With support for both angle and C-channel profiles, this machine delivers high-speed, low-waste processing and integrates seamlessly into production environments requiring reliability and output.

Key Features:

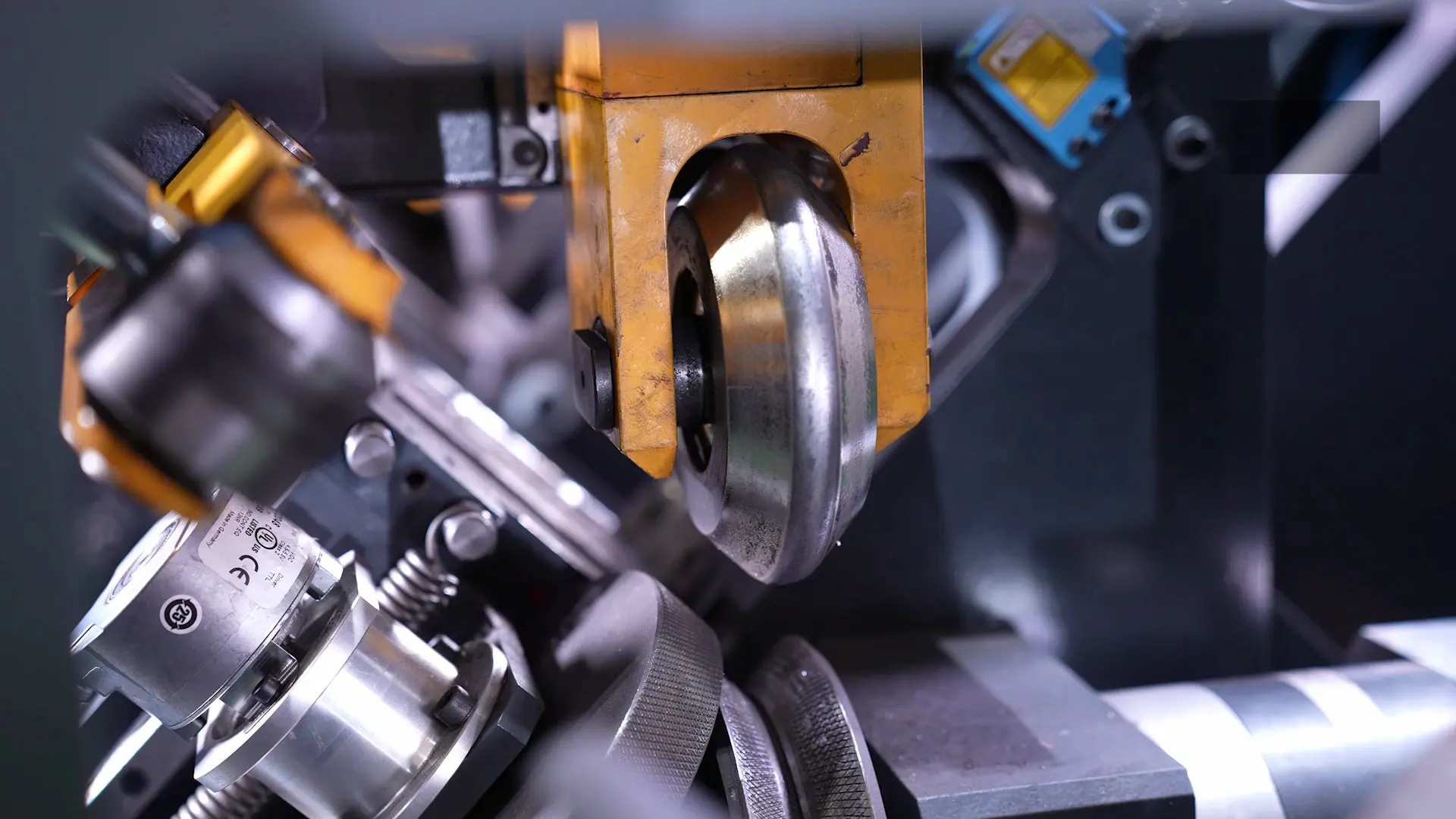

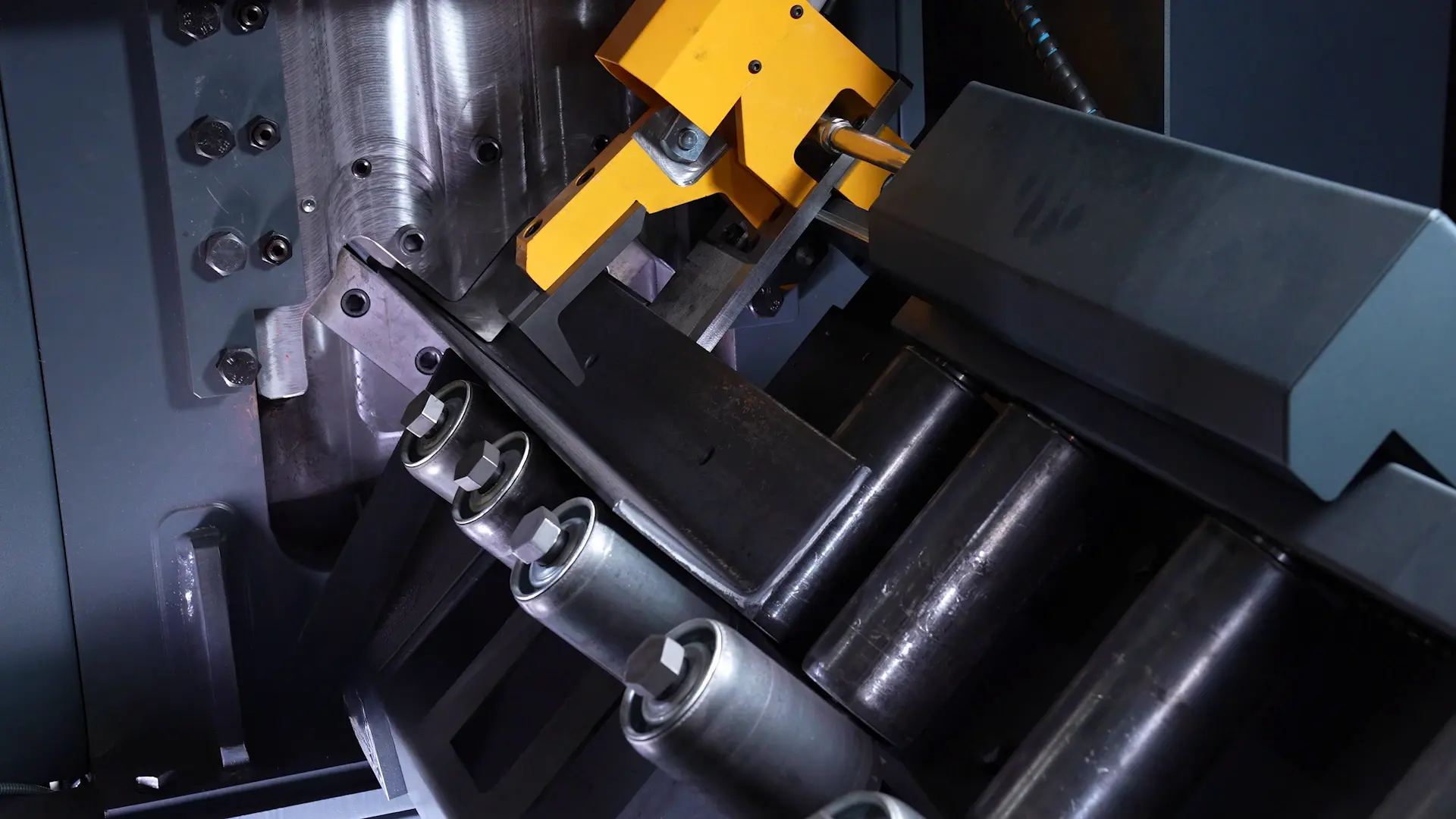

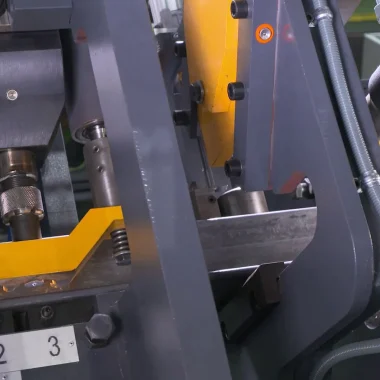

Punching Unit:

- Up to three punches per leg for flexible layouts

- CNC-controlled positioning with automatic backmark adjustment

- Quick-change punch/die system for reduced tooling downtime

- Punching capacity up to Ø31 mm in 15 mm thick material

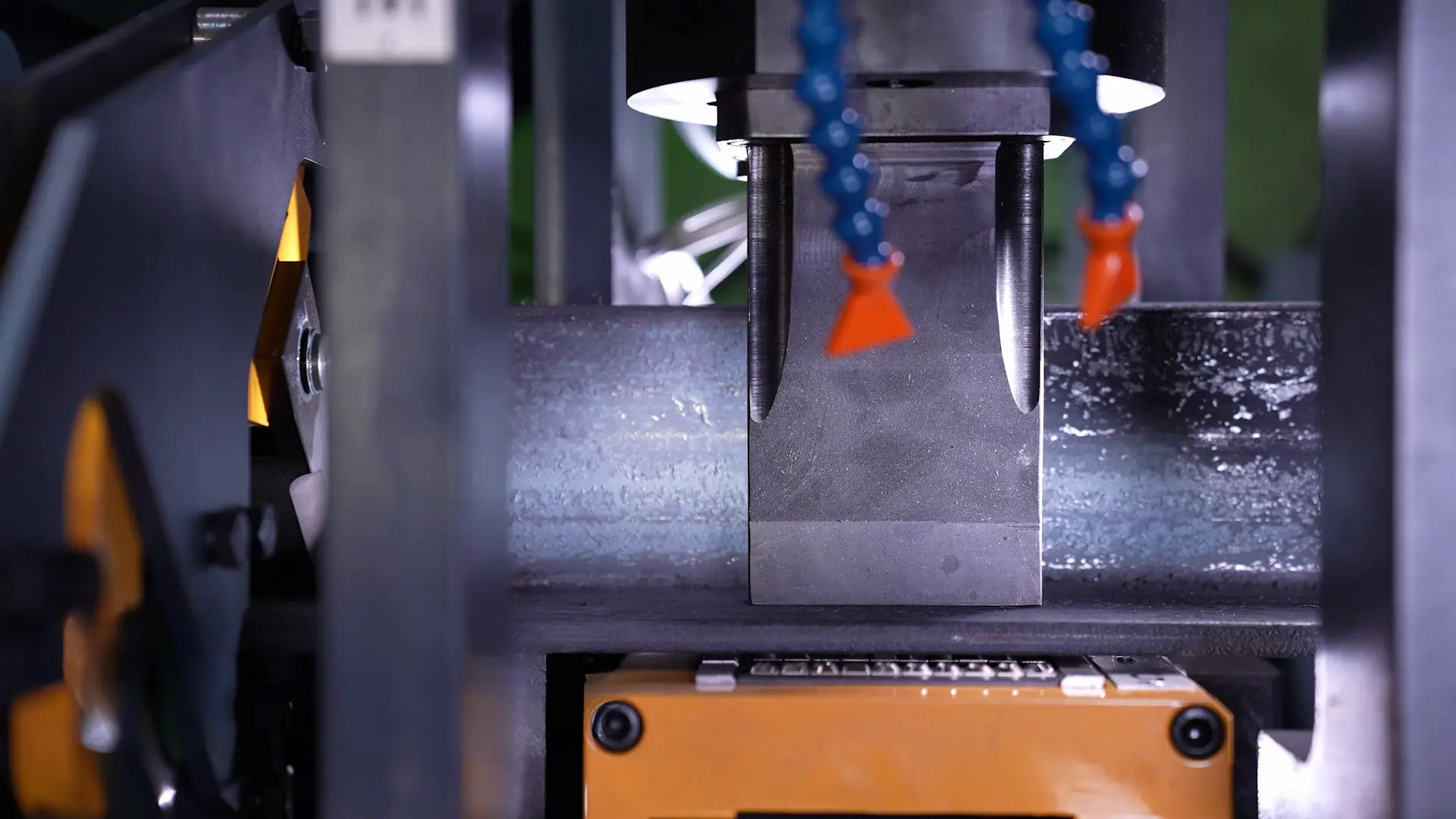

Shearing Unit:

- Up to 330 tons of shearing force (depending on model)

- Zero-waste shearing station for material efficiency

- Quick-access blade holder and CNC-adjustable stroke

- Supports angle sizes up to L-180x180x18 mm

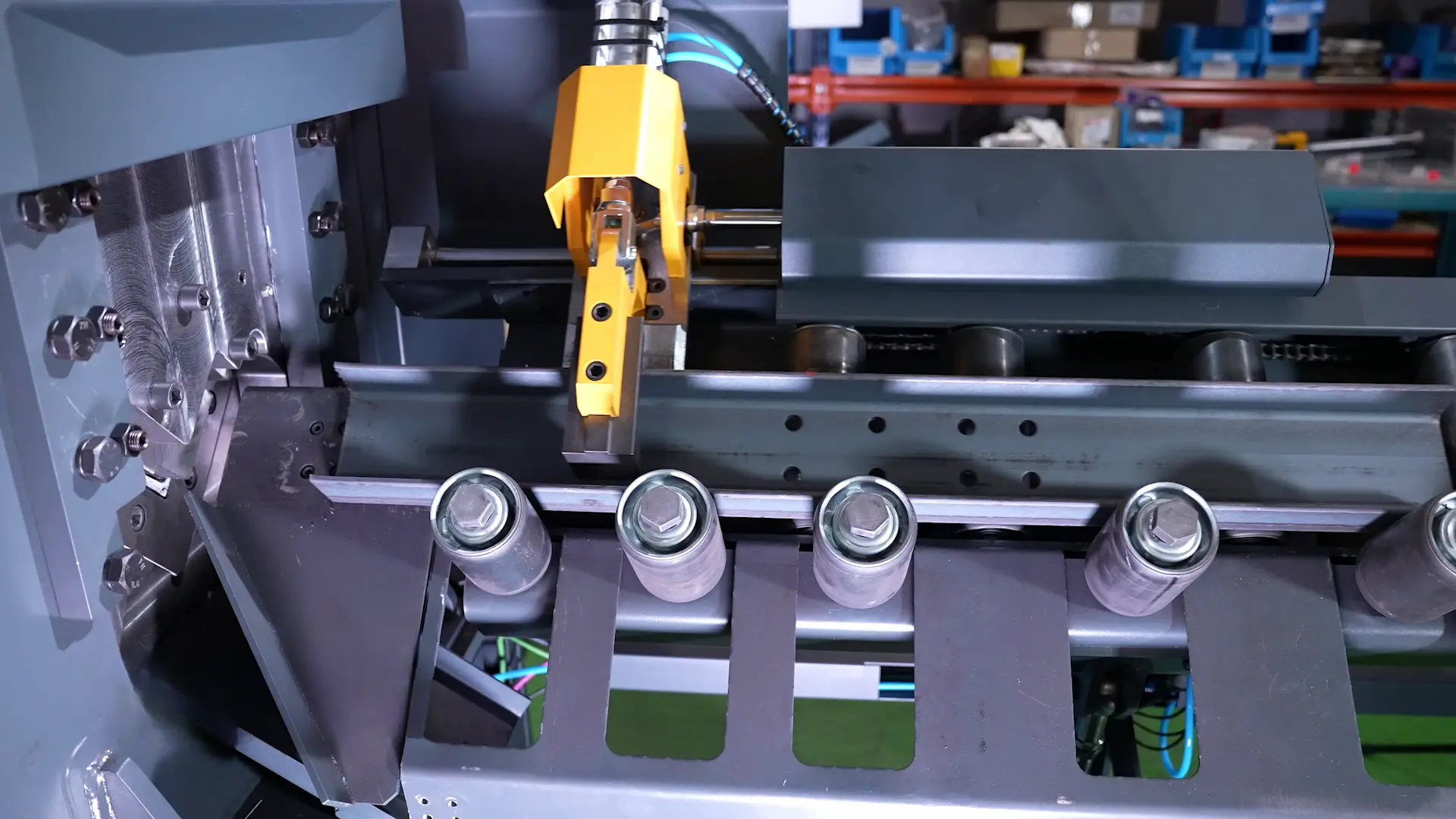

Material Handling & Feeding:

- CNC-controlled traction rollers with rotary encoder accuracy (±0.15 mm/m)

- Feed speeds up to 45 m/min (model dependent)

- Rack-and-pinion infeed system with gravity loading tables

- Automatic loading/unloading and optional roller extensions for 12-meter profiles

Marking System:

- Alphanumeric part and serial marking

- Cassette and wheel options for permanent traceability

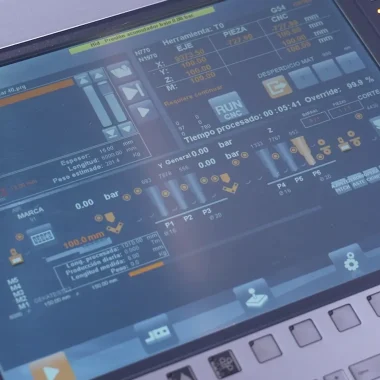

Software & Automation:

- Integrated Zero Waste System minimizes scrap to just 40 mm

- Hydraulic cooling and air conditioning support extended-duty cycles

- Modular loading/unloading conveyors in 2–3 meter sections for layout flexibility

Technical Highlights (Model Range):

- Min Angle Size: from 1-1/4″ x 1-1/4″ x 1/8″

- Max Angle Size: up to 7″ x 7″ x 11/16″

- Max Flat Bar Size: up to 7″ x 11/16″ (model dependent)

- C-Channel Capability: up to 5″

- Punching Power: from 37 to 88 tons

- Shearing Power: from 72 to 330 tons

The FMS Beam Processing Line is a powerful, flexible addition to any solar structure production facility, delivering speed, precision, and material savings—all in one integrated system.

Reviews

There are no reviews yet.