Drill and Saw Line for Structural Solar Components

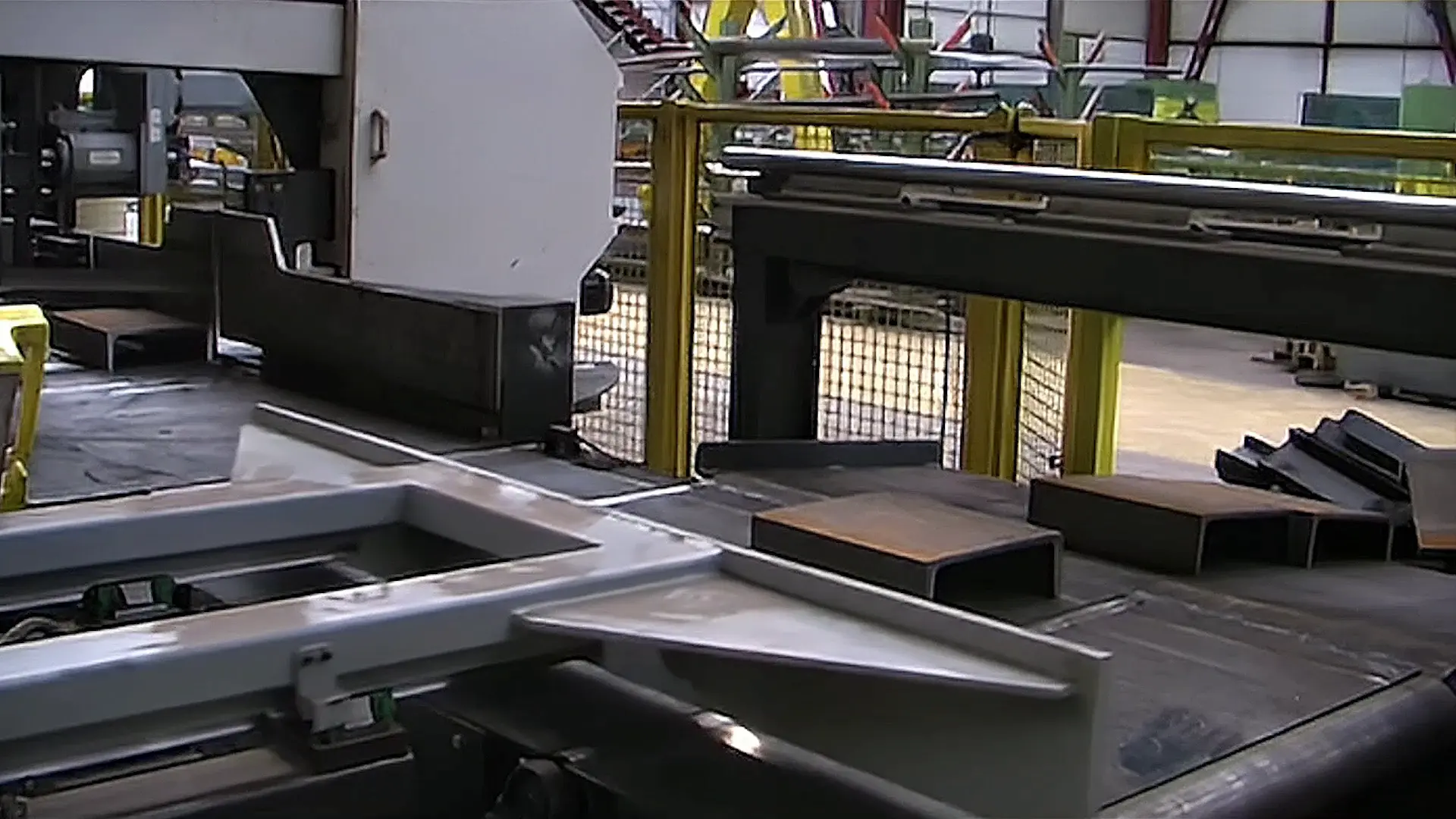

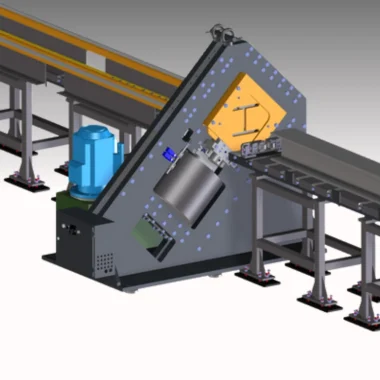

The FMS Drill & Saw Line, powered by the GK DSB series, combines high-speed CNC drilling with precision bandsaw cutting in a single, robust machine. Engineered for structural steel, C-channel, and profile processing, this fully integrated system delivers unmatched productivity, accuracy, and versatility for manufacturers of solar structures and heavy steel frameworks.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

The FMS Drill & Saw Line, powered by the GK DSB series, combines high-speed CNC drilling with precision bandsaw cutting in a single, robust machine. Engineered for structural steel, C-channel, and profile processing, this fully integrated system delivers unmatched productivity, accuracy, and versatility for manufacturers of solar structures and heavy steel frameworks.

Key Features:

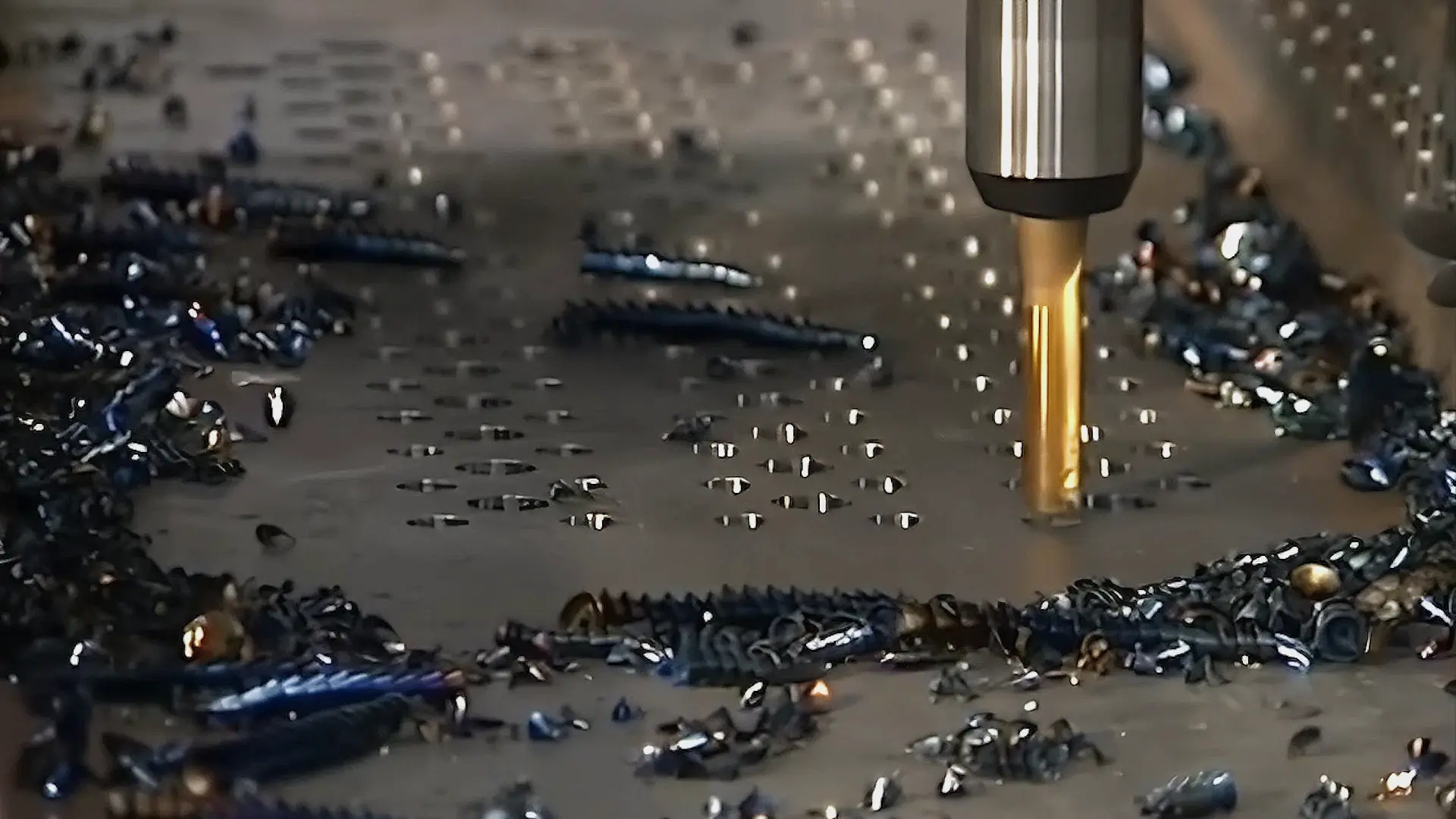

3-Spindle Drilling Unit

- Three independently controlled heads: two horizontal, one vertical

- Supports drilling, countersinking, tapping, and counterboring

- Automatic tool changer for fast, hands-free transitions

- Laser calibration for tool length and collision avoidance

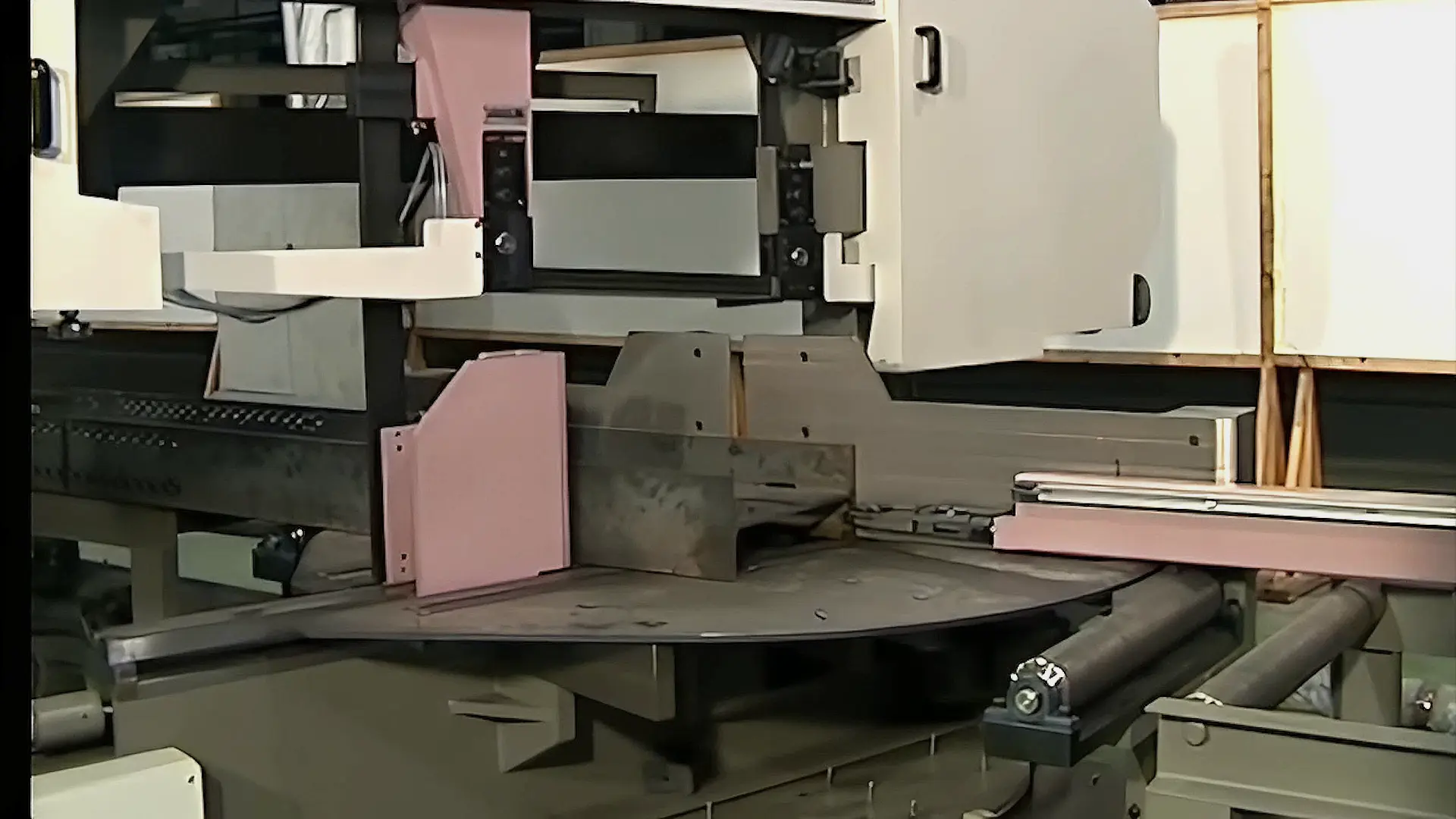

Sawing Unit with Mitre Capability

- Precision sawing for straight and mitre cuts from +45º to -60º

- Frequency-controlled blade speed for optimized cutting

- Motorized blade brush ensures clean, accurate cuts

- No repositioning needed when switching between straight and mitre cuts

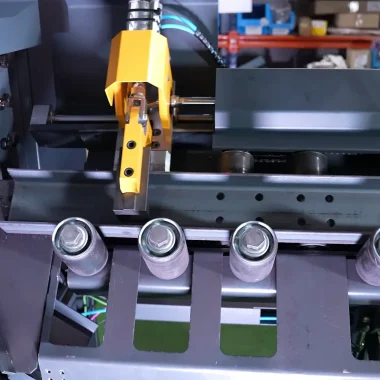

Material Clamping & Handling

- Hydraulic vertical and horizontal clamping

- CNC-controlled gripper system with up to 14 meters of travel

- Manual 90º turning gripper for complex profile orientations

- Infeed rollerway with vertical alignment rollers

Clean & Efficient Lubrication

- Air-oil mist lubrication system with triple outlets

- Compatible with both internal and external tool cooling

- Low-waste operation for clean and efficient cutting

Advanced Sensing & Laser Systems

- Laser detection for profile start and width

- Automatic material width sensing via clamp sensors

- Integrated laser calibration to ensure tool precision and avoid collisions

Smart CNC Control System

- Windows 10 control panel with touch interface

- Compatible with TEKLA, DSTV, and industry-standard formats

- USB and Ethernet connectivity for fast file transfer

- Includes LANTEK Flex3D programming suite for drilling and sawing simulation

Available in multiple configurations, the DSB line accommodates structural profiles up to 47″ wide, drilling diameters up to 1.57″, and mitre cutting without repositioning—offering a scalable solution for any structural steel or solar tracking manufacturer seeking to integrate high-performance drilling and sawing in a single pass.

Reviews

There are no reviews yet.