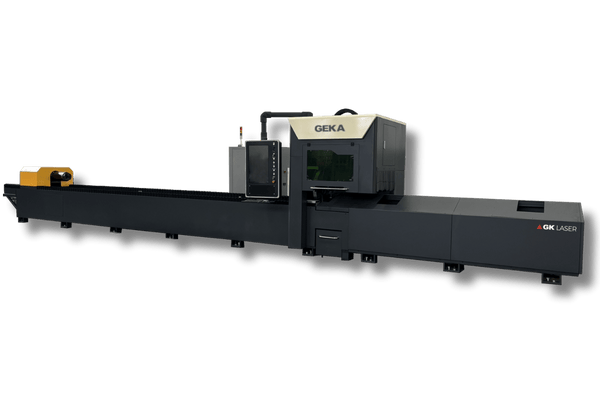

Laser Cutting Machine for Solar Pipe and Profile Sections

The FMS Laser Cutting Machine is a high-performance system designed to process pipes, beams, and structural profiles with exceptional speed and precision. With bevel-cutting capabilities and support for a wide range of shapes and sizes, it’s the ideal solution for solar tracker manufacturers and structural steel fabricators seeking flexible, clean, and accurate cutting in a single operation.

Need something slightly different?

- We offer models beyond what’s listed here.

- Custom configurations available to fit your needs.

- Reach out — we’ll help you find the right fit.

Description

The FMS Laser Cutting Machine for Solar Pipe and Profile Sections delivers precision, efficiency, and flexibility for cutting steel pipes, tubes, and structural profiles. Ideal for manufacturers of solar tracker structures and heavy fabrication components, this advanced system supports straight and bevel cuts on a wide range of profiles — including tubes, angles, channels, and beams — all with minimal waste and maximum productivity.

Key Features:

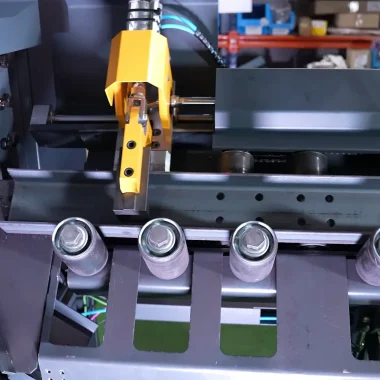

Universal Clamping System

- Pneumatic chucks with 8-cylinder technology for double the holding force

- Compatible with round, square, rectangular, oval, angle, C-channel, I-beam, and other profiles

- Ranges from Ø15 mm to Ø220 mm standard (custom chucks available up to Ø365 mm)

- Compact rear chuck reduces scrap to just 150 mm

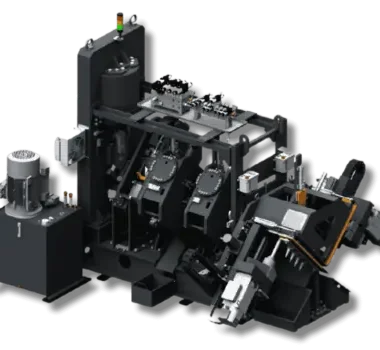

Reinforced Structural Design

- Heavy-duty frame reduces internal stress and increases cutting precision

- Cam-support system stabilizes long tubes to prevent deflection during cutting

- Built for consistent high-quality performance in demanding environments

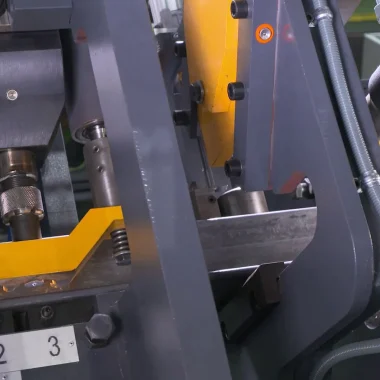

5-Axis Bevel Cutting Head

- Automatic focusing head with full 5-axis movement

- Enables complex bevel cuts for weld preparation

- Supports straight cuts, line cuts, and hole patterns on various profiles

High-Power Laser Capability

- Fiber laser source from 2 kW up to 20 kW

- Uniform energy distribution for clean cuts in thick materials

- Low energy consumption with high-speed throughput

Semi-Automatic Loading & Unloading

- Reduces handling time and improves cycle efficiency

- Ideal for high-volume structural steel and solar pipe production

Smart CNC Control & Software

- Embedded control panel with user-friendly interface

- Supports file import, nesting, bevel path programming, and collision detection

- Compatible with TEKLA, DSTV, and other industry-standard file formats

Available in multiple configurations, the GK LASER line processes tubes from 6 to 12 meters in length and handles diameters up to 365 mm. It’s a budget-smart solution that delivers premium cutting performance, low scrap, and unmatched versatility in pipe and profile fabrication for solar and structural industries.

Reviews

There are no reviews yet.